Picture this: it’s the first truly cold night of the season. You turn up the thermostat expecting warm, comfortable heat to fill your home. Instead, you hear strange clanking sounds, smell something unusual, or worse, nothing happens at all. Your boiler has chosen the absolute worst time to fail.

This scenario plays out in countless New Jersey homes every winter. Homeowners ignore subtle warning signs during the fall, assuming their boiler will make it through one more season. Then winter arrives with its brutal temperatures, and suddenly a minor issue becomes a full-blown emergency requiring expensive repairs and leaving families shivering while waiting for service.

Your boiler is trying to tell you it needs help long before it completely fails. The key is learning to recognize these warning signs and taking action while you still have time to schedule convenient, cost-effective repairs.

Why Fall is Critical for Boiler Repair

Your boiler sits mostly idle during the warmer months. Components settle, seals dry out, and minor issues that would be obvious during regular operation go completely unnoticed. When you fire up your system for the first time in months, all these dormant problems suddenly wake up.

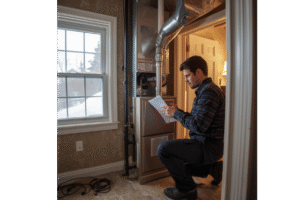

This is exactly why savvy homeowners in Woodland Park and Bergen County schedule boiler inspections every fall. The goal isn’t just routine maintenance; it’s catching developing problems before they leave you without heat during January’s coldest stretch.

Boiler repairs cost significantly less when you’re not in emergency mode. You have time to compare options, schedule service at your convenience, and avoid the premium rates that come with after-hours emergency calls. Plus, addressing small problems now prevents the cascading failures that turn a simple repair into a complete system replacement.

Think of it like your car. You wouldn’t ignore the check engine light and hope everything works out fine. Your boiler deserves the same attention, especially considering how much you depend on it during New Jersey winters.

Strange Noises That Demand Attention

A properly functioning boiler operates relatively quietly. Sure, you’ll hear the occasional click as it cycles on and off, but loud or persistent noises signal problems that need professional attention.

Banging or clanking sounds, often called “kettling,” indicate sediment buildup on your heat exchanger. Over time, minerals in your water supply accumulate and restrict water flow. This causes water to boil and steam to form, creating those alarming banging noises. Left unchecked, kettling dramatically reduces efficiency and can cause your heat exchanger to crack, an expensive repair that might require complete boiler replacement.

Gurgling or bubbling sounds suggest air trapped in your system. While not immediately dangerous, trapped air prevents proper circulation and creates cold spots throughout your home. Air in the lines also puts extra stress on your circulator pump, potentially leading to premature failure of this critical component.

Whistling or hissing noises often point to pressure problems. Your boiler operates within a specific pressure range, and sounds like these indicate the system is struggling to maintain proper pressure. This could result from a failing pressure relief valve, a leak somewhere in the system, or problems with your expansion tank.

Grinding or screeching sounds from your circulator pump mean worn bearings or a failing motor. Pumps don’t heal themselves. These noises progressively worsen until the pump fails completely, leaving you with a boiler that runs but produces no heat.

Hearing unusual noises from your boiler?

Don’t wait until it stops working completely. M&S Technician provides expert boiler diagnostics and repair throughout Woodland Park and Morris County. We’ll identify the source of those sounds and fix the problem before it becomes an expensive emergency. Call (908) 528-0535 to schedule service.

Leaks and Moisture Issues

Water where it doesn’t belong is never a good sign. Even small leaks around your boiler indicate problems that will worsen over time and potentially cause significant damage to your home.

Puddles directly under your boiler suggest seal failures, corrosion, or cracks in the tank or pipes. The source matters. A small drip from a valve or connection might be a simple fix, while water coming from the tank itself often signals serious problems that may require replacement.

Corrosion or rust on your boiler or nearby pipes indicates moisture has been present for a while. Rust doesn’t appear overnight. By the time you notice visible corrosion, underlying damage has already compromised your system’s integrity. Corroded components are weak points that will fail under pressure, especially during peak heating season when your boiler works hardest.

Moisture or water stains on walls or ceilings near your boiler room suggest leaks in pipes running through your home. These hidden leaks waste energy, reduce heating performance, and can cause serious structural damage to your property. They also create perfect conditions for mold growth, which presents health risks beyond the heating problems.

Check your boiler’s pressure gauge regularly. If you find yourself frequently adding water to maintain proper pressure, you have a leak somewhere in the system. Even if you can’t see where water is escaping, it’s going somewhere, and finding that leak prevents bigger problems down the road.

Inconsistent Heating Throughout Your Home

Your boiler should heat your entire home evenly. When some rooms feel comfortable while others stay cold, your system is telling you something isn’t working correctly.

Radiators or baseboard heaters that don’t warm up indicate circulation problems. The issue could be as simple as trapped air that needs bleeding or as complex as a failing circulator pump, zone valve problems, or pipe blockages. Either way, inconsistent heating means your boiler is working harder than necessary to heat your home, wasting energy and money while failing to keep you comfortable.

If your boiler runs constantly but struggles to reach the set temperature, it’s losing efficiency. This could result from sediment buildup reducing heat transfer, a failing heat exchanger, incorrect burner settings, or the system simply aging beyond its effective service life. Running constantly also dramatically increases wear on all components, accelerating the timeline toward complete system failure.

Temperature fluctuations where your home feels too hot one moment and too cold the next suggest problems with your thermostat, zone controls, or aquastat settings. These controls regulate when and how your boiler operates, and malfunctions create uncomfortable conditions while stressing your equipment.

Pay attention to how long your boiler runs to heat your home. If cycles seem longer than previous years or if the system runs constantly during moderate weather, efficiency has declined significantly. This not only impacts your comfort but also shows up as higher fuel bills throughout the winter.

Rising Energy Bills Without Explanation

Your heating costs should remain relatively consistent from year to year, accounting for fuel price changes and weather severity. A sudden spike in your heating bill with no obvious explanation indicates your boiler is losing efficiency.

Compare your current fuel consumption to previous years during similar weather conditions. If you’re burning significantly more fuel to maintain the same temperature, your boiler is working harder to produce the same amount of heat. This inefficiency results from problems like sediment buildup, failing components, incorrect combustion settings, or simply the natural decline that occurs as equipment ages.

Short cycling, where your boiler turns on and off frequently rather than running in longer, more efficient cycles, wastes tremendous amounts of fuel. This behavior often indicates oversized equipment, faulty controls, or pressure problems. Beyond the wasted money, short cycling puts enormous stress on your boiler and dramatically shortens its lifespan.

Keep an eye on your utility bills starting in early fall. A gradually increasing trend before you’re even using heat regularly suggests your boiler is struggling. Addressing these efficiency problems now, before peak heating season, prevents wasted money all winter long.

Rising energy bills often signal repair needs that, once addressed, actually pay for themselves through reduced fuel consumption. Professional boiler repair in Woodland Park from M&S Technician restores your system’s efficiency, reducing your heating costs while ensuring reliable performance all winter. Contact us at (908) 528-0535 for an efficiency evaluation.

Visible Signs of Age and Wear

Sometimes your boiler shows visible signs that it’s struggling. These physical indicators deserve attention even if the system still seems to be heating adequately.

Soot or scorch marks around your boiler indicate incomplete combustion. Your boiler should burn fuel cleanly and completely. Soot buildup means combustion isn’t happening efficiently, which wastes fuel, reduces heat output, and can produce dangerous carbon monoxide. This is an immediate safety concern that requires professional inspection.

Yellow or orange flames instead of blue signal combustion problems. Gas-fired boilers should produce a steady blue flame. Yellow or orange coloring indicates the fuel-to-air mixture isn’t correct, resulting in incomplete combustion and potential carbon monoxide production. Never ignore flame color changes.

Cracks in the heat exchanger represent serious problems. Heat exchangers develop cracks from thermal stress and corrosion over time. These cracks allow combustion gases to mix with the air in your home, creating carbon monoxide hazards. Unfortunately, cracked heat exchangers typically require boiler replacement rather than repair.

Age itself is a factor. Most boilers last 15 to 20 years with proper maintenance. If your system is approaching or exceeding this range, increased problems are inevitable. Even if repairs are possible, the cost-benefit analysis often favors replacement, especially when you factor in the improved efficiency of modern equipment.

Pilot Light and Ignition Problems

For boilers with standing pilot lights, the flame should be steady and blue. Problems with your pilot light indicate issues that need addressing before they leave you without heat.

A pilot light that frequently goes out suggests problems with the thermocouple, a safety device that detects whether the pilot is lit. A faulty thermocouple will shut down your gas supply even when the pilot is burning, causing repeated outages. Draft issues, gas pressure problems, or a dirty pilot assembly can also cause repeated pilot failures.

Electronic ignition systems have their own warning signs. If you hear your boiler attempting to ignite multiple times before successfully lighting, or if it fails to ignite at all, sensors or ignition components are failing. These problems worsen over time and eventually prevent your boiler from operating.

Delayed ignition, where gas builds up before igniting with a small boom, is dangerous. This condition, called “rollout,” creates safety hazards and indicates serious problems with your ignition system or burner assembly. Never ignore delayed ignition or small explosions when your boiler starts.

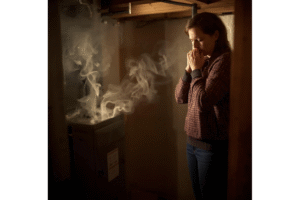

The Smell Test for Boiler Problems

Your nose can detect boiler problems before other symptoms appear. Certain smells always warrant immediate attention.

The smell of gas, which utilities add a sulfur or rotten egg odor to for safety, indicates a leak. If you smell gas near your boiler or anywhere in your home, evacuate immediately, don’t use any electrical switches or create sparks, and call your gas company from outside your home. Gas leaks are life-threatening emergencies that require immediate professional response.

A metallic or burning smell when your boiler first fires up each season is normal as accumulated dust burns off. However, persistent burning odors suggest overheating, electrical problems, or components failing. These smells shouldn’t continue beyond the first few hours of operation.

Musty or damp smells in your boiler room indicate moisture problems. Even if you don’t see obvious leaks, moisture allows mold growth and accelerates corrosion of your boiler and associated components.

When Repair Becomes Replacement

Sometimes the signs you’re seeing indicate your boiler has reached the end of its useful life. Knowing when to repair versus replace saves money and prevents repeated breakdowns.

The 50 percent rule provides good guidance. If repair costs exceed 50 percent of replacement cost and your boiler is more than 15 years old, replacement typically makes better financial sense. You’re investing significant money into equipment that will soon face additional problems.

Frequent repairs over the past few years suggest cascading failures. Once major components start failing, others typically follow quickly. If you’ve called for service multiple times recently, your boiler is telling you it’s worn out.

Modern high-efficiency boilers offer tremendous advantages over older equipment. New systems can achieve 95 percent efficiency or higher compared to 70 to 80 percent for older boilers. This efficiency improvement reduces heating costs by 20 to 30 percent, meaning a new boiler can partially pay for itself through lower fuel bills.

For commercial properties in Bergen County and Morris County, boiler reliability isn’t just about comfort; it’s about business continuity. Repeated failures disrupt operations, and emergency repairs cost substantially more than planned replacements. Commercial HVAC installation from M&S Technician includes proper sizing, professional installation, and ongoing maintenance plans that keep your business running smoothly.

Take Action Before Winter Arrives

Every warning sign discussed here represents a problem that will worsen with time and use. Your boiler won’t heal itself, and hoping it makes it through one more season is a gamble with steep stakes: your family’s comfort, safety, and potentially thousands of dollars in emergency repairs or property damage.

Fall is the perfect time to address boiler problems. Technicians have greater availability, you can schedule service at your convenience, and repair costs are lower when you’re not in crisis mode. Most importantly, you’ll have confidence that when winter arrives with its bitter temperatures, your heating system will perform reliably.

M&S Technician has served homeowners and businesses throughout Woodland Park, Bergen County, and Morris County with honest, expert boiler service for years. We diagnose problems accurately, explain your options clearly, and perform repairs that last. Whether your boiler needs a simple tune-up or is showing signs that replacement makes more sense, we’ll give you the information you need to make the best decision for your home and budget.

Our technicians are trained on all boiler types and brands. We stock common replacement parts, which means we can often complete repairs in a single visit. And if your boiler’s problems indicate that boiler installation in Woodland Park is the smarter choice, we’ll help you select the right system and install it properly for years of reliable, efficient service.

Don’t gamble with your winter comfort. If you’ve noticed any of these warning signs, call M&S Technician at (908) 528-0535 or visit mstechnicians.com to schedule a comprehensive boiler inspection today. We’ll identify any developing problems and ensure your system is ready for whatever winter brings.