Every HVAC contractor in Bergen County expects you to call in July when your air conditioner dies during a heat wave, or in December when your furnace quits on Christmas Eve. That’s when demand is highest, schedules are packed, and prices reflect the urgency of desperate homeowners who need equipment now. Whether your family wants HVAC upgrades or is in need of AC repair, winter is the most cost effective and efficient time to jump in.

But here’s what most homeowners in Woodland Park and Morris County don’t realize: January is actually the absolute best time for HVAC upgrades, and it’s not even close.

You’re probably thinking this sounds like a sales pitch designed to drum up business during a slow month. And yes, January is slower for HVAC contractors. But that slowness creates advantages for homeowners that translate into thousands of dollars in savings, better equipment selection, superior installation quality, and a level of service you simply cannot get during peak season.

At M&S Technician, we’re going to share something most contractors won’t tell you: waiting for peak season to replace your HVAC system costs you more money in almost every measurable way. Not because of some complicated financial scheme, but because of simple supply and demand economics combined with the realities of how the HVAC industry operates.

Today we’re breaking down exactly why January upgrades deliver better value, how much you actually save, and how to take advantage of this window before everyone else figures it out.

The Pricing Reality: What You Actually Pay in January vs. July

Let’s start with the most compelling reason to upgrade in January: you’ll pay significantly less for identical equipment and installation.

Manufacturer pricing cycles favor winter installations. HVAC manufacturers plan production based on seasonal demand forecasts. They ramp up manufacturing in late winter and spring to build inventory for summer installation season. During January, they’re sitting on inventory from last season that they need to move before new model years arrive.

This creates promotional pricing, rebates, and dealer incentives that simply don’t exist during peak demand months. Manufacturers would rather discount equipment in January to keep production lines running than carry inventory into the next model year.

These aren’t small discounts. We’re talking about $500-1,500 in manufacturer incentives on complete system installations. That’s money that goes directly back to you, the homeowner, reducing your total investment.

Contractor pricing flexibility is highest in January. During July and August, HVAC contractors are turning away work because they’re booked solid for weeks. During December, they’re charging emergency premiums for holiday service. In January, installation schedules open up and contractors compete for available work.

This competition benefits you. Contractors are more willing to negotiate on labor costs, waive certain fees, or include additional services at no charge when they’re trying to fill January installation slots. That same flexibility doesn’t exist when they have more work than they can handle during peak season.

Emergency premiums don’t apply. When your air conditioner fails during a July heat wave, you’re not comparison shopping and negotiating. You’re accepting whatever pricing contractors quote because you need relief now. Emergency service premiums can add 30-50% to installation costs compared to planned replacements.

January installations are planned, not reactive. You’re choosing to upgrade from a position of control, which means you pay normal pricing without any emergency or urgency premiums.

Total savings comparison: A furnace and AC system that costs $8,000-9,000 installed in July might cost $6,500-7,000 installed in January once you factor in manufacturer promotions, contractor flexibility, and the absence of emergency pricing. That’s $1,500-2,000 in savings for identical equipment and service.

Over the 15-20 year life of your HVAC system, you’ll never recoup that $2,000 you overpaid by waiting for peak season. That money is simply gone, paid unnecessarily because you didn’t time your purchase strategically.

The Installation Quality Difference Nobody Talks About

Price matters, but installation quality determines whether your new equipment delivers its promised efficiency, reliability, and lifespan. January installations receive attention to detail that’s simply impossible during peak season rushes.

Technicians have time to do it right. During July, installation crews are under pressure to complete 2-3 installations per day to keep up with demand. They’re working long hours in extreme heat, rushing through jobs to stay on schedule, and cutting corners (often unintentionally) because there’s another desperate customer waiting.

In January, installation crews can dedicate a full day to your installation without the pressure of multiple jobs backed up. They can take time for proper load calculations, careful equipment placement, precise ductwork modifications, and thorough testing of all system functions.

The difference between a rushed installation and a careful one dramatically impacts system performance. Improper refrigerant charging alone can reduce efficiency by 20% and shorten compressor life by years. Inadequate airflow testing can leave you with comfort problems that persist for the entire life of your system.

M&S Technician’s January installations receive the time and attention that ensure your system performs exactly as designed. We don’t rush, we don’t cut corners, and we don’t compromise quality to meet impossible schedules.

Access to the best installation crews. Every HVAC company has their A-team of most experienced, most skilled installers. During peak season, these teams are spread thin across multiple jobs. Some installations get assigned to newer, less experienced crews simply because there aren’t enough veteran installers to handle demand.

In January, you’re much more likely to get top-tier installation crews because scheduling flexibility allows companies to assign their best people to every job. Experience matters tremendously in HVAC installation, where dozens of critical decisions impact long-term performance.

Fewer scheduling complications and delays. Peak season installations get rescheduled constantly due to emergency service calls, unexpected complications on previous jobs, parts delays, and weather issues. You might take a day off work for installation only to receive a call that morning saying they need to reschedule.

January installations stay on schedule because there aren’t emergency calls pulling installers away from planned work. When we commit to a date, we show up and complete your installation as promised.

Post-installation support is more available. If any issues arise after installation (rarely, but it happens), getting return service in January is quick and easy. During peak season, you might wait days or weeks for return visits because companies are overwhelmed with new emergencies.

The Equipment Selection Advantage

Upgrading in January gives you better equipment options and more time to make informed decisions without pressure.

Full model availability. By July, certain high-efficiency models and specific sizes are often on backorder because manufacturers can’t keep up with demand. You might wait weeks for equipment to arrive, or you might have to settle for your second or third choice because your first choice isn’t available.

January inventory is fully stocked. Manufacturers have completed their production ramps, distributors have inventory on hand, and you can choose exactly the equipment you want without compromise.

Time to research without crisis pressure. When your AC dies in July, you’re making decisions in crisis mode. You don’t have time to research different brands, compare efficiency ratings, read reviews, or evaluate warranty options. You’re choosing between whatever contractors can install quickly.

January gives you the luxury of time. You can research thoroughly, compare multiple quotes, read about different equipment brands, and make genuinely informed decisions based on your priorities rather than whoever can install fastest.

Opportunity to evaluate emerging technology. HVAC technology advances constantly. Variable-speed compressors, smart thermostats with AI learning, zoned comfort systems, and advanced air quality equipment become available regularly.

When you’re researching in January without crisis pressure, you have time to understand these technologies and evaluate whether they’re worth the investment for your specific situation. Crisis replacements often default to basic equipment simply because there’s no time to consider alternatives.

Better financing terms. Many manufacturers offer promotional financing during slow periods to stimulate sales. Zero-percent financing for 24-60 months is common in January but much less common during peak demand months.

Even if you could pay cash, zero-percent financing is financially advantageous. Keep your money invested and make comfortable monthly payments with no interest charges. Crisis replacements rarely qualify for these promotional terms.

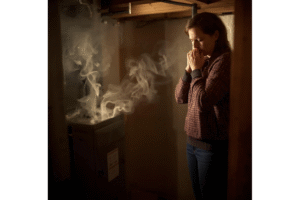

The Hidden Costs of Waiting for Peak Season

Beyond the direct price premium, waiting for summer or an emergency costs you in ways most homeowners never consider.

Every month of inefficient operation costs real money. If your current system is 15+ years old and operating at 65% efficiency, you’re wasting hundreds of dollars between January and July when you finally replace it. A modern 95% efficient system would save you $50-80 per month in energy costs.

Six months of operation with your inefficient system wastes $300-480 that never comes back. That’s lost money that could have partially paid for your new system.

You risk emergency breakdown during peak season. An aging system you’re planning to replace soon might limp through winter but die during the first heat wave. Now you’re forced into emergency replacement at peak season pricing with no negotiating leverage.

The “save a few more months” of operation often backfires, costing you far more in emergency premiums than you’d have paid for planned January replacement.

You’re gambling with comfort during extreme weather. Emergency replacements during heat waves might require 1-2 weeks to complete between equipment availability and installation scheduling. That’s potentially two weeks without AC during the hottest days of summer.

January installations happen under mild conditions with no discomfort during the installation day. Even if installation takes longer than expected, you’re not suffering.

The compounding stress factor. Emergency replacements during extreme weather involve multiple stressors hitting simultaneously. Uncomfortable home conditions, financial pressure to make quick decisions, worry about family members (especially children or elderly), and the logistical challenges of being without HVAC all combine to create significant stress.

Planned January replacements involve zero stress. You’re making calm, informed decisions about equipment, scheduling installation at your convenience, and never experiencing discomfort.

How Building Cycles and Tax Incentives Favor January

Beyond pricing and availability, January timing aligns perfectly with financial incentives and construction industry cycles.

Tax credit timing works in your favor. Federal energy efficiency tax credits for HVAC equipment reset annually. By installing in January 2026, you can claim credits on your 2026 tax return filed in early 2027, getting your refund quickly.

Install in December and you file in just a few months. Install in July and you wait 6-8 months after installation to file. January installations maximize the time you have to plan for tax benefits while minimizing the wait for refunds.

Current federal tax credits for high-efficiency equipment can be worth $300-600 or more depending on equipment efficiency ratings. State and utility company rebates add another $300-1,500 in potential savings. Combined, these incentives can reduce your net cost by $1,000-2,000.

M&S Technician helps navigate all available incentives and handles paperwork to ensure you capture every dollar available. We stay current on changing incentive programs so you don’t miss opportunities.

Utility company rebate funds are fully allocated. Many utility companies allocate specific budgets for energy efficiency rebates each year. By summer, these funds are often depleted and new applicants get waitlisted until the next budget year.

January applicants access fresh annual budgets when funds are fully available. You’re guaranteed to receive promised rebates rather than hoping funds don’t run out before your application processes.

Construction season planning. If your HVAC upgrade is part of larger home improvements like renovations, additions, or whole-home projects, January installation allows you to coordinate with other trades during their slower periods.

General contractors, electricians, and other trades also have better availability in winter. You can coordinate all improvements during the same period, often at better pricing across all trades.

The Weather Advantage for Installation Quality

Counter-intuitively, winter is actually better for HVAC installation quality than summer in several important ways.

Moderate temperatures allow better quality control. Installing HVAC equipment in 95-degree attics or crawlspaces is miserable and dangerous for installers. Heat exhaustion and dehydration affect concentration and decision-making.

January installations in New Jersey happen in moderate conditions where installers can work comfortably and carefully. Better working conditions directly translate to better installation quality.

Proper equipment testing is easier in winter. Testing a new furnace’s heating performance in January provides immediate feedback. You can verify heat output, temperature rise, and comfort delivery under actual heating load conditions.

Installing a furnace in July means testing with outdoor temperatures in the 80s, providing no real-world validation of heating performance. You won’t know if there are heating problems until next winter when addressing them is more complicated.

Ductwork modifications are more comfortable. If your installation includes ductwork changes or sealing, this work happens in unconditioned spaces like attics and crawlspaces. Doing this work in January is uncomfortable, but doing it in July is brutal.

Comfortable installers do better work. That’s human nature, and it’s another quality factor favoring winter installations.

No cooling season disruption. Installing in January means your new system is fully broken in and proven reliable before you depend on it for cooling during summer heat. Any minor adjustments or tweaks happen during mild weather when you’re not dependent on your HVAC for survival.

Installing in July means you’re immediately depending on brand-new, untested equipment during the most demanding time of year. If any issues arise, you’re troubleshooting under high-stress conditions.

The “But I Need My Furnace” Myth

The biggest objection to January HVAC upgrades is obvious: “I need my furnace working right now, I can’t be without heat.”

This concern is valid but overstated. Here’s the reality of January installations:

Installation takes one day. Complete HVAC system replacement typically requires 6-10 hours. Your home is without heat for less than a full day, often just 4-6 hours if replacing furnace only.

Installations are scheduled for mild weather when possible. We watch forecasts and schedule installations for days with moderate temperatures. On a 40-degree January day, your home loses minimal heat during installation.

We work efficiently to minimize disruption. Our installation crews understand homeowners need heat, especially in winter. We arrive prepared, work efficiently, and prioritize getting your system operational as quickly as possible without sacrificing quality.

Backup heat options exist. For installations during colder stretches, we can discuss temporary heating solutions like electric space heaters for critical areas. These aren’t ideal long-term solutions, but they’re perfectly adequate for a few hours during installation.

Compare this to summer AC installation. Would you rather be without heat for 6 hours on a 45-degree January day, or without AC for a full day during a 95-degree July heat wave? The January discomfort is minimal and easily managed compared to summer installation scenarios.

The “I need my heat” concern keeps many homeowners from capturing January advantages even though the actual disruption is minor and manageable.

What January Upgrades Look Like in Practice

Let’s walk through what actually happens when you choose January for HVAC upgrades, removing the mystery and uncertainty.

Step 1: Initial consultation and assessment (Week 1). You contact M&S Technician and schedule a home assessment. We evaluate your current system, calculate proper sizing for replacement equipment, assess ductwork condition, and discuss your comfort priorities and budget.

This consultation takes 60-90 minutes and provides comprehensive information about your options. We present multiple equipment choices at different price points, explain efficiency ratings and expected operating costs, and provide detailed written quotes.

Step 2: Research and decision (Week 1-2). You take time to review proposals, research equipment brands we’ve recommended, verify financing options, and make an informed decision without pressure. This is the luxury that January timing provides.

Step 3: Order equipment (Week 2). Once you’ve decided, we order your specific equipment. January lead times are typically 3-7 days compared to 2-4 weeks during peak season. Equipment arrives quickly, and we schedule installation at your convenience.

Step 4: Pre-installation preparation (Week 3). Before installation day, we review the plan with you, confirm timing, explain what to expect, and answer any remaining questions. You know exactly what’s happening and when.

Step 5: Installation (Week 3-4). On installation day, our crew arrives as scheduled, removes old equipment, installs new system, tests all functions thoroughly, and ensures everything operates perfectly before leaving.

Step 6: Post-installation support. We follow up after installation to ensure you’re satisfied and the system is performing as expected. Any questions or concerns receive immediate attention.

Total timeline: 3-4 weeks from first call to completed installation. That’s faster than most peak-season installations even though there’s no emergency driving the schedule.

The Economics of Acting Now vs. Waiting

Let’s put concrete numbers to the January advantage so you can see exactly what waiting costs.

Scenario: Replacing 15-year-old furnace and AC system

January installation costs:

- Equipment: $6,500 (with winter promotions)

- Installation labor: $1,500

- Total: $8,000

- Less manufacturer rebates: $800

- Less utility rebates: $600

- Net cost: $6,600

July emergency installation costs:

- Equipment: $7,500 (regular pricing, no promotions)

- Installation labor: $2,000 (includes emergency premium)

- Total: $9,500

- Less manufacturer rebates: $300 (limited availability)

- Less utility rebates: $0 (funds depleted)

- Net cost: $9,200

January advantage: $2,600 in savings

Add energy waste while waiting (Jan-July):

- Monthly waste with old inefficient equipment: $75

- Six months of waste: $450

- Total advantage of January installation: $3,050

That’s $3,000 that stays in your pocket by acting in January instead of waiting for summer emergency. That’s real money that could fund a vacation, pay down other debt, or boost your emergency fund.

Over the 15-year life of your new system, that $3,000 represents a 45% return on your maintenance and energy savings. Few investments deliver that kind of return with zero risk.

Special Considerations for Different Property Types

January upgrade advantages vary slightly based on your property type.

Single-family homeowners get maximum benefit because installation scheduling is entirely flexible. You control timing and can choose optimal installation dates.

Multi-unit property owners benefit enormously from winter installations because tenant disruption is minimal. Installing HVAC in vacant units between tenants is ideal, and winter typically has lower tenant turnover.

Commercial property owners should absolutely prioritize winter HVAC work. Installing during slow business periods minimizes customer disruption and employee discomfort. The operational advantages of winter installation far outweigh any minor heating disruption.

Rental property investors get better contractor availability and pricing for upgrading multiple properties. If you’re upgrading HVAC in several rental units, scheduling all installations in January captures volume discounts that aren’t available during busy season.

Common January Upgrade Mistakes to Avoid

Even homeowners who recognize January advantages can stumble with poor planning or unrealistic expectations.

Waiting for emergency failure before committing. If you know your system needs replacement soon, don’t gamble on it lasting through winter. Once it fails, you’ve lost the planning advantage and might end up in emergency replacement mode anyway.

Make the decision while your system still works, then replace on your schedule.

Focusing only on equipment cost. The cheapest equipment isn’t always the best value. Focus on total cost of ownership including energy costs, expected lifespan, and warranty coverage. Sometimes spending $1,000 more upfront saves $3,000 over the system’s life.

Skipping proper sizing calculations. Bigger isn’t better with HVAC equipment. Oversized systems cycle frequently, waste energy, and create comfort problems. Undersized systems run constantly and struggle to maintain temperature.

Insist on proper load calculations, not just matching your old equipment’s capacity. Your home’s needs might have changed due to insulation improvements, window replacements, or occupancy changes.

Not verifying contractor credentials and insurance. January might bring out contractors offering deals that seem too good to be true. Verify licensing, insurance, manufacturer certifications, and references before committing.

M&S Technicians carries full licensing and insurance, maintains manufacturer certifications for all major brands, and provides references upon request. We’re established members of the Woodland Park and Bergen County community, not transient contractors chasing quick sales.

Ignoring ductwork needs. New equipment won’t perform well with old, leaky, inadequate ductwork. If your ducts need attention, address this during installation when access is easiest and costs are lowest.

How to Maximize Your January Advantage

If you’re ready to take advantage of January timing, these steps ensure you capture maximum benefit.

Act early in January. Don’t wait until late January when contractors’ schedules start filling for late winter and early spring work. Early January offers best availability and flexibility.

Get multiple quotes but prioritize value over price. Compare proposals from 2-3 reputable contractors, but don’t automatically choose the cheapest. Evaluate equipment quality, warranty terms, installation approach, and contractor reputation.

Bundle related improvements. If you need ductwork improvements, air quality equipment, or thermostat upgrades, bundling these with your main installation often reduces total cost compared to separate projects.

Verify all available incentives. Ask contractors to detail all manufacturer rebates, utility rebates, and tax credits your installation qualifies for. Make sure these are included in your net cost calculations.

Plan installation for mid-week if possible. Weekend installation often costs more or isn’t available from top contractors. Mid-week installation typically offers better pricing and crew availability.

Prepare your home before installation day. Clear access to your mechanical room, attic access, and outdoor unit locations. Remove items stored near your furnace. This preparation allows installers to work efficiently without delays.

The M&S Technicians January Advantage

When you choose M&S Technicians for January HVAC upgrades, you get advantages beyond what we’ve already discussed.

Transparent pricing with no hidden fees. Our quotes include everything: equipment, installation, disposal of old equipment, permits if needed, and basic materials. You know the total cost upfront with no surprises on installation day.

Top-tier equipment from leading manufacturers. We install Carrier, Lennox, Trane, and other premium brands known for reliability and efficiency. We don’t push proprietary equipment or no-name brands with questionable support.

Experienced installation crews, not subcontractors. Our installers are M&S Technician employees, not subcontractors. They’re trained to our standards, accountable to our reputation, and committed to quality work that reflects well on our company.

Comprehensive warranty coverage. New equipment includes manufacturer warranty on parts (typically 10 years). We warranty our installation work separately, ensuring you’re protected if any issue arises from installation quality.

Post-installation optimization. We return after your first month of operation to verify everything is performing optimally and make any minor adjustments needed. This follow-up ensures your system delivers promised efficiency and comfort.

Local service and support. We’re based in your community, serving Woodland Park, Bergen County, and Morris County. We’re here for the long term, providing maintenance and service for the life of your equipment.

Stop Waiting, Start Saving

You’ve seen the numbers. You understand the advantages. January HVAC upgrades deliver better pricing, superior installation quality, more equipment choices, and less stress than peak season replacements.

The question isn’t whether January is the best time to upgrade. The question is whether you’ll act on this knowledge or wait until summer emergency forces your hand at much higher cost.

Call M&S Technicians today at (908) 528-0535 to schedule your free consultation and equipment assessment. We’ll evaluate your current system, discuss your options, provide detailed pricing for equipment that fits your needs and budget, and show you exactly how much you’ll save with January installation.

January appointments are filling quickly as smart homeowners recognize this opportunity. Don’t wait until late January when the window starts closing. Act now while you have maximum scheduling flexibility and can capture the best promotional pricing.

Schedule your HVAC upgrade consultation now and join the homeowners who understand that the best HVAC deals don’t happen during peak demand. They happen when you plan ahead, act strategically, and take control of your investment timing.

Winter installation means summer comfort at winter prices. That’s an advantage too valuable to ignore.

For more information the cost benefits of HVAC upgrades and assessing which is the best fit for you, learn more from The Department of Energy.